How To Avoid Spring Back For Sheet Metal

Stretch forming is often a more effective solution to springback problems than direct compensation.

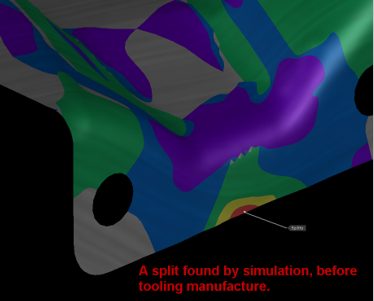

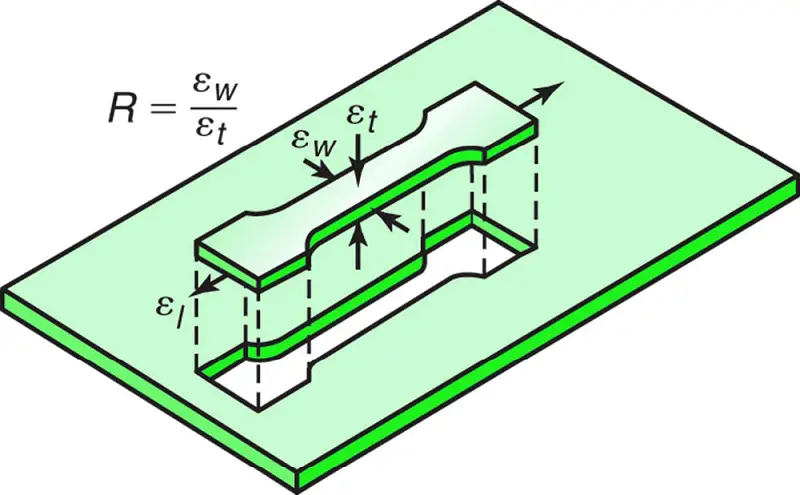

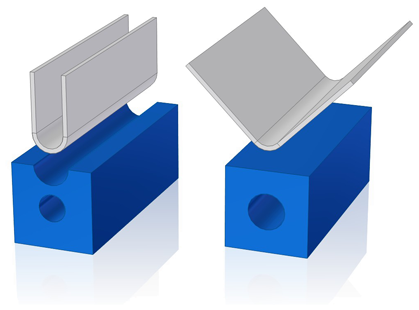

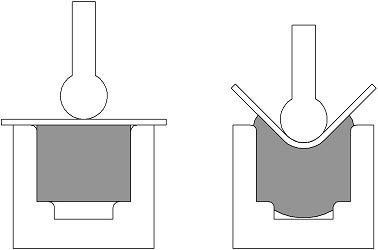

How to avoid spring back for sheet metal. The method is to apply the tangential tension when the sheet metal is bent change the stress state and distribution inside the sheet metal and make the whole section within the scope of plastic tensile deformation. Bending is one of the most frequent actions done to metal in press brake operation. Due to the fact the sheet metal work hardens during forming drawing it is desirable to stretch a sheet metal part as much as possible to increase part strength and thereby increase the rigidness of the part and lessen the effect of springback. If the flange is springing back 5 degrees outboard overbending the flange 5 more degrees inboard should result in a better part.

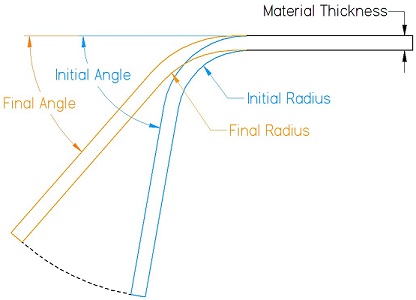

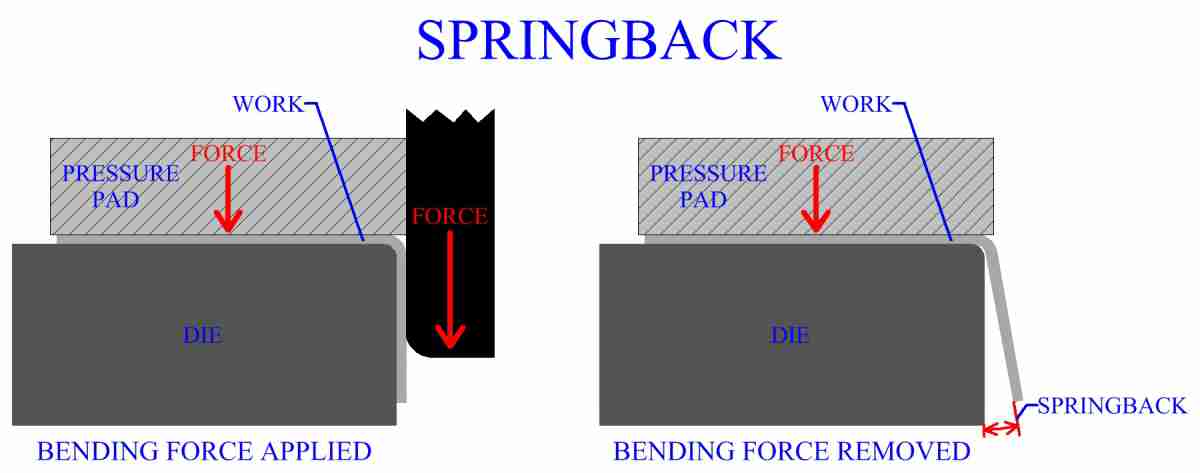

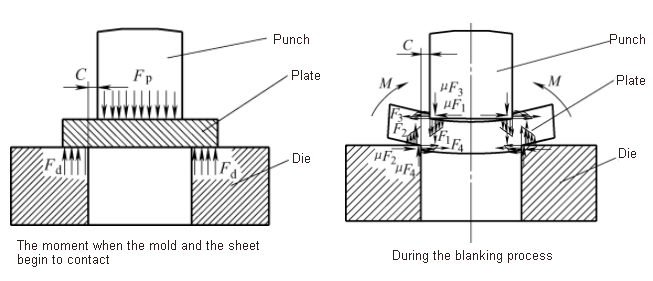

Springback is known as the reaction when. Simple straight line bending will exhibit springback produce a simple 90 degree bend in any given sheet metal thickness of any grade and springback will occur. The formation of sheet metal requires elastic plastic bending and stretching of the metal which contributes to springback. The required tonnage is often prohibitive.

This type of springback problem is easily adjusted for by adding simple over bend or compensation. When compensating for spring back in materials such as stainless steel coining is typically not the best option unless you are working with thin gauges. After these unloading the internal and external springback offset each other which cause the springback reduced finally. Let s say you have a 90 degree bending angle and the material springs back 2 degrees to an 88 degree bent angle complementary.

Apart from these two factors the die gap or clearance and sheet metal thickness also has a very appreciating amount of effect on springback from this analysis it shown that an sufficient amount of die gap has to be maintained same as thickness of the sheet metal in order to compensate the springback and also to avoid some of the defects such as tearing. However for membrane or combined modes of springback this is not always realistic. Springback is how the sheet metal tries to revert back into its straight form once it is bent.