How To Bend Aluminum Sheet With Heat

This is a highly technical and potentially dangerous process best left to a professional metalworker.

How to bend aluminum sheet with heat. Proper bending can be done with annealing the aluminum first although it s not an ideal candidate for formed parts. In the event that you are bending a thick piece of sheet metal you can apply heat from a blowtorch along the seam of your bend line to facilitate your bend. A brake is a device that allows you to bend a piece of sheet metal at a particular angle. It can be tricky to bend the aluminum tubes without them cracking or at least turning white.

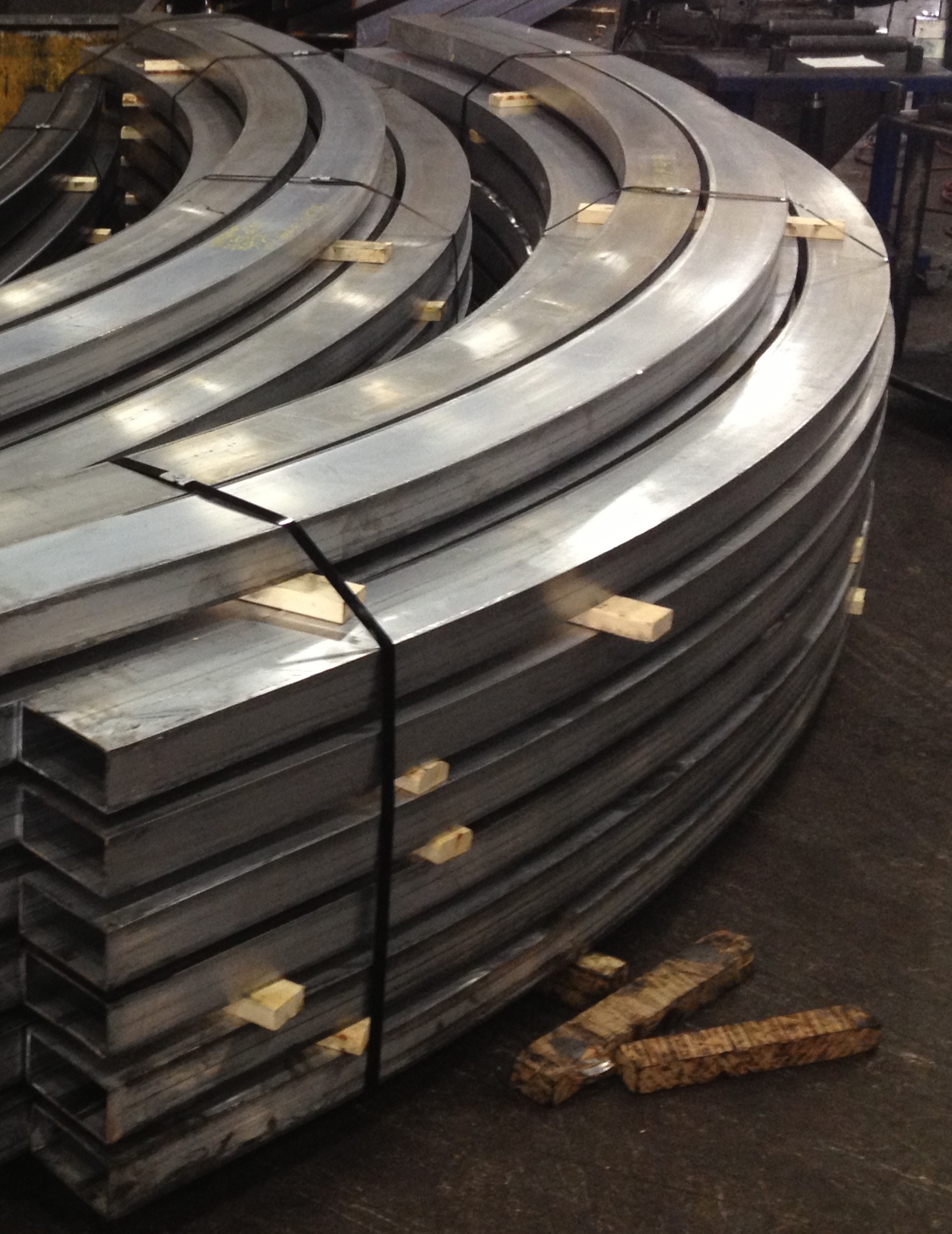

Place the fracture line over the edge of a table and bend the overhang slightly downwards. Material thickness and inside bend radius just like all sheet metal aluminum work hardens during the forming process. With added copper magnesium silicon and zinc the aluminum becomes heat treatable. A bending brake will be best suited for shaping flat square sheets of light gauge aluminum.

Sheet aluminium can be cut without the need for a guillotine or tin snips which tend to deform the metal. Heavy gauge aluminum bars or rods must be heat bent using an acetylene torch and vice. Clamp the metal to the table making sure the edge of the angle iron aligns with the edge of the table. That is it gets stronger and harder by working bending it.

Metal shops have brakes mounted at different angles with automated braking arms however it is possible to bend sheet metal at home without the use of a brake. When working with sheet metal one particularly useful piece of equipment is the brake. This weakens the aluminium and creates a fracture line. You can not bend a sharp 90 degree angle or the aluminum will crack and break heat will help but it will also weaken the metal.

Keep in mind that many kinds of fabricated metal have extremely high melting points and applying your torch injudiciously could cause damage or do harm to your sheet metal or equipment. Annealing them is a great way of having tube that s retained its strength. Grain direction bend line should go across the grain for the best bend having said that a typical sharp 90 bend on a piece of 1 8 aluminum sheet should be a minimum 1 8 inside radius use either 3003 or 5052 ideally the bend line should go across the grain. Align the bend area of the aluminium sheet with the edge of the table.

You need to use something as a guide to give your bend a small radius. Press one edge of a wood board against the angle iron. This will give you a nice bend. Put one end of the aluminum in a vise and use a piece of 1 4 black pipe or a 1 2 bolt to bend the aluminum around to achieve your angle without trying to force the metal into a sharp 90degree bend.

Press toward the ground with both hands to bend the aluminium sheet. If you re making something structural with tubes you might want to flatten the ends so you can drill them to pass a bolt through securely.