How To Brace A Large Roof System For Shear

The swenson shear stone coat cutter is designed for use on a multitude of metal roof applications from stone coated metal shake and shingles to 14 gauge stainless flat sheets.

How to brace a large roof system for shear. Step 3 brace first truss to ground. Generally a brace connection such as the simple shear connection for an infill beam that is located within the one third depth of the beam web that is closest to the compression flange can be considered to provide. However when it comes to installing an expansion joint filler the joint system must now be capable of handling the expected movements in shear at each jog in the run of the joint. Residential structures framing systems typically consist of the roof structure that supports the roof.

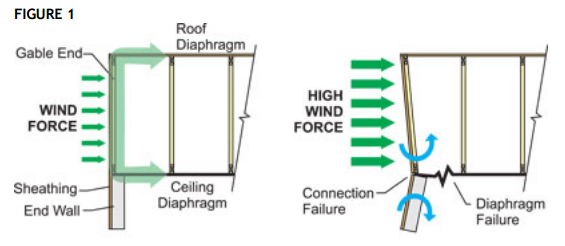

In order to keep those roofs and walls right where they re supposed to be a sturdy connection to a shearwall below is required. T profile strapping and l profile strapping are designed to be installed by inserting one leg of the strapping into a 1 2 in deep kerf cut into the studs and plates and then nailing the strapping to each stud and plate. A direct brace may be provided for a primary member by a properly attached floor system itself or by a secondary framing member. Wooden stud walls have to be properly shear braced with structural construction panels in accordance with the local code such as the international residential code.

Deck exterior and interior load bearing walls beams girders posts and floor framing. When wind or earthquake forces are applied to the house the floors and roofs want to move sideways. They work in both compression and tension. Walls supporting multiple stories have greater racking loads than those supporting only a roof.

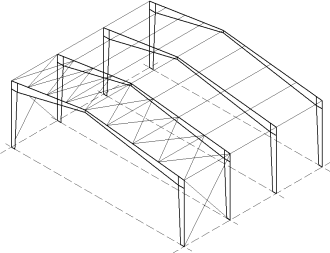

The base and ridge bender is a combination tool used for bending stone coated steel to control water from blowing into the metal roof system. Nail braces vertically every 4 feet along the top and bottom of a gable truss. The diagram below shows a simple roof floor and wall relationship. The panels should be continuous from top to bottom.

Slide the rest of the truss up using a 2x4 as a ramp if necessary. Buildings in higher hazard areas with large design wind speeds or earthquake ground motions experience greater potential racking load. Lower story walls serve to. T profile and l profile strapping have an important advantage over flat strapping.

Install 2x4s at a 45 degree angle. The basic rule of thumb is to have a minimum of 4 of 7 16 osb on each corner and no less than 25 apart. The size of the building and how many stories are supported by a braced wall line. Shear walls or steel moment frames in homes with large windows or other large openings provide the strength to resist lateral loads.