Loadmaster Roof Deck Assembly

Reduced operational maintenance costs.

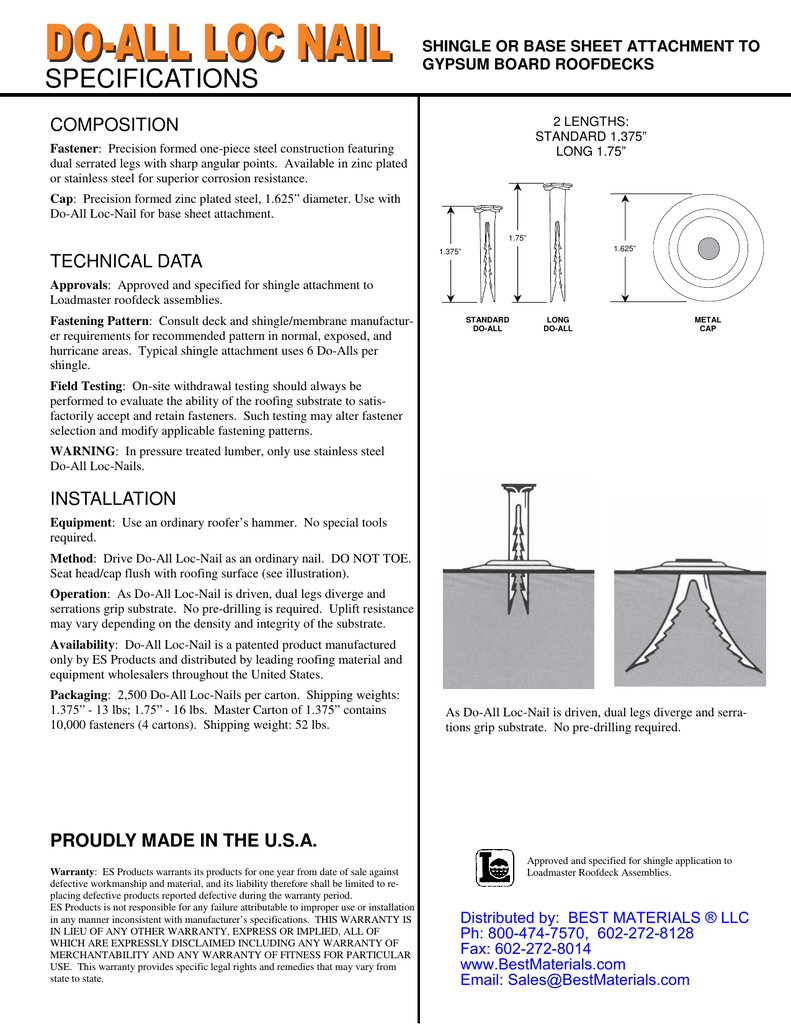

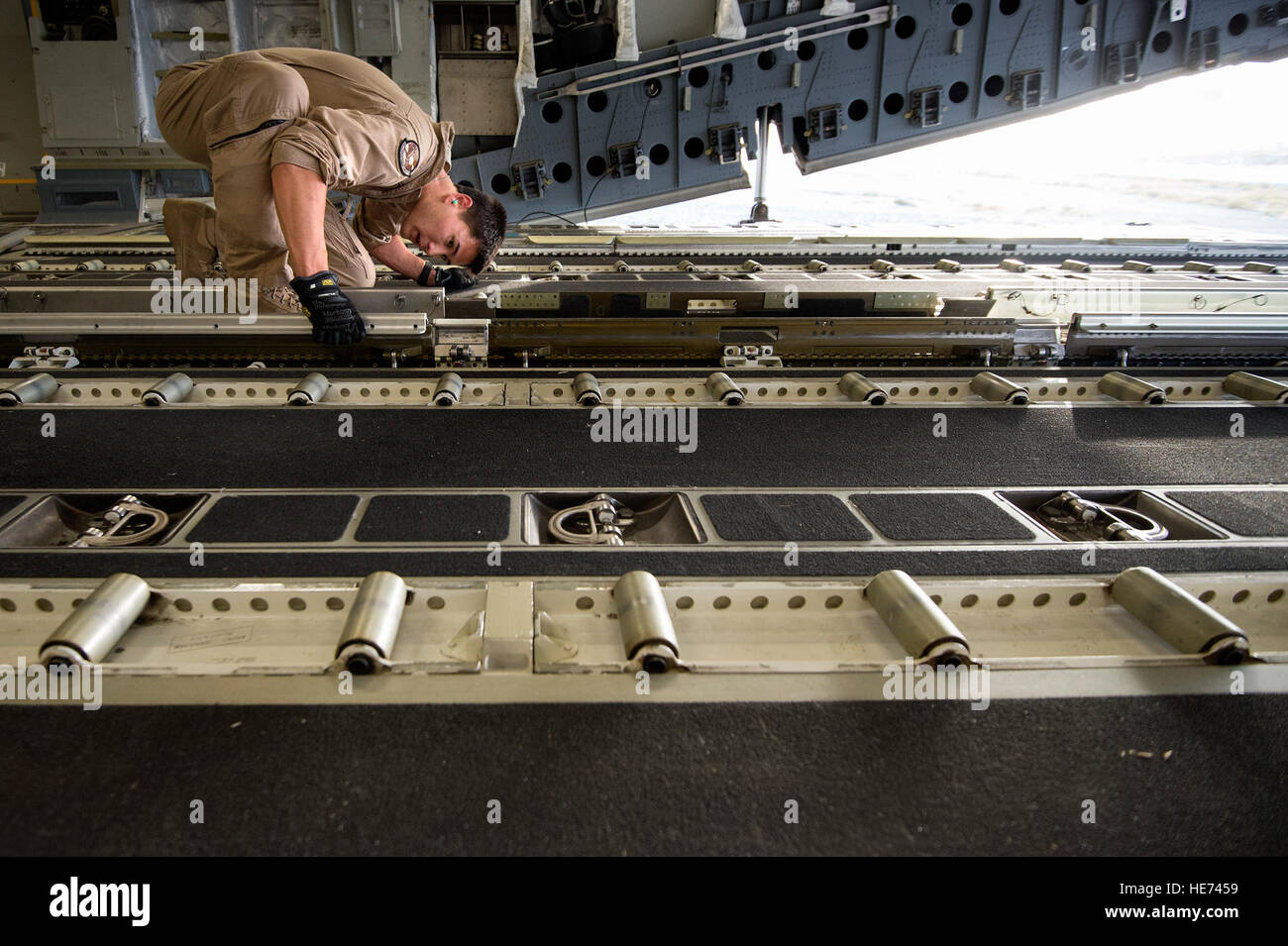

Loadmaster roof deck assembly. Due to the composite action of the integrated parts and advanced engineering of the loadmaster system it has the performance characteristics required for a roof deck assembly to function as a proper roofing substrate. Considering a roof deck as a story may be acceptable when the height of the deck does not exceed 2 3 stories depending on the construction type and. Loadmaster is an engineered roof deck system composed of a high tensile steel sections with thermal insulation and high performance duraflex mineral board mechanically anchored to the steel sections with engineered attachments to provide structural composite strength. In essence the loadmaster warranty provides protection similar to insurance protection.

Loadmaster offers warranties on all roof decks utilizing roof coverings by manufacturers who have been tested and passed the ibc wind uplift requirements in conjunction with a loadmaster roof deck assembly. Loadmaster retrofitting provides economical solutions for situations where an existing loadmaster or lightweight insulating concrete assembly has lost composite action. Loadmaster roof deck assemblies have been fully tested and qualified by fm ul and all major code organizations for both wind uplift non combustibility and fire resistance. The entire roof assembly loadmaster roof deck roof covering must be wind uplift tested as a unit to establish its wind uplift resistance and code compliance.

For current information on metal roofing systems tested and approved in conjunction with loadmaster contact loadmaster s technical department at 800 527 4035.